Lithium-ion Battery: How It Works

Learn how lithium-ion batteries work and are manufactured in this viral video sponsored by LG Energy Solution and General Motors.

Lithium-ion batteries are the crucial components that power modern electric vehicles, making them possible. In a recent Engineering Explained video sponsored by LG Energy Solution, host Jason Fenske takes viewers on a tour of LG's battery plant in Holland, Michigan, showcasing the process of manufacturing these essential batteries.

LG Energy Solution is a major player in the EV battery industry, partnering with General Motors in the Ultium Cells LLC joint venture to build four U.S. battery plants to supply GM EVs. The company's involvement in the production of lithium-ion batteries is a key factor in the advancement of electric vehicle technology.

The construction of a lithium-ion battery involves four main components: the cathode, anode, electrolyte, and separator. The cathode and anode serve as the positive and negative terminals, respectively, while the electrolyte acts as the medium through which lithium ions and electrons flow during the charging and discharging process. The separator is essential in preventing short circuits by keeping the cathode and anode from coming into contact with each other.

The cathode, often the most expensive part of a battery, plays a crucial role in the overall cost of an electric vehicle. Materials such as nickel manganese cobalt (NMC) and lithium iron phosphate (LFP) are commonly used in the construction of cathodes, with LFP being viewed as a more affordable and sustainable option due to its use of fewer scarce raw materials.

Anodes, on the other hand, are typically made from graphite, which has the capacity to store large amounts of lithium. However, silicon is emerging as a potential alternative due to its ability to store even more lithium, potentially boosting EV range. Despite its advantages, silicon anodes come with challenges, such as significant expansion and contraction as they absorb and release lithium.

The electrolyte in current lithium-ion batteries is a liquid composed of lithium salts, a solvent, and various additives. This liquid allows lithium ions to move freely between the cathode and anode, without reacting with other materials in the battery. While solid-state batteries, with a solid electrolyte, have been under investigation, liquid electrolytes remain the industry standard for now.

The separator, a porous material, allows lithium ions to pass through while also acting as a safeguard against overheating by closing its pores at high temperatures. This crucial component ensures the safe and efficient flow of lithium ions between the anode and cathode, powering the electric vehicle's motors.

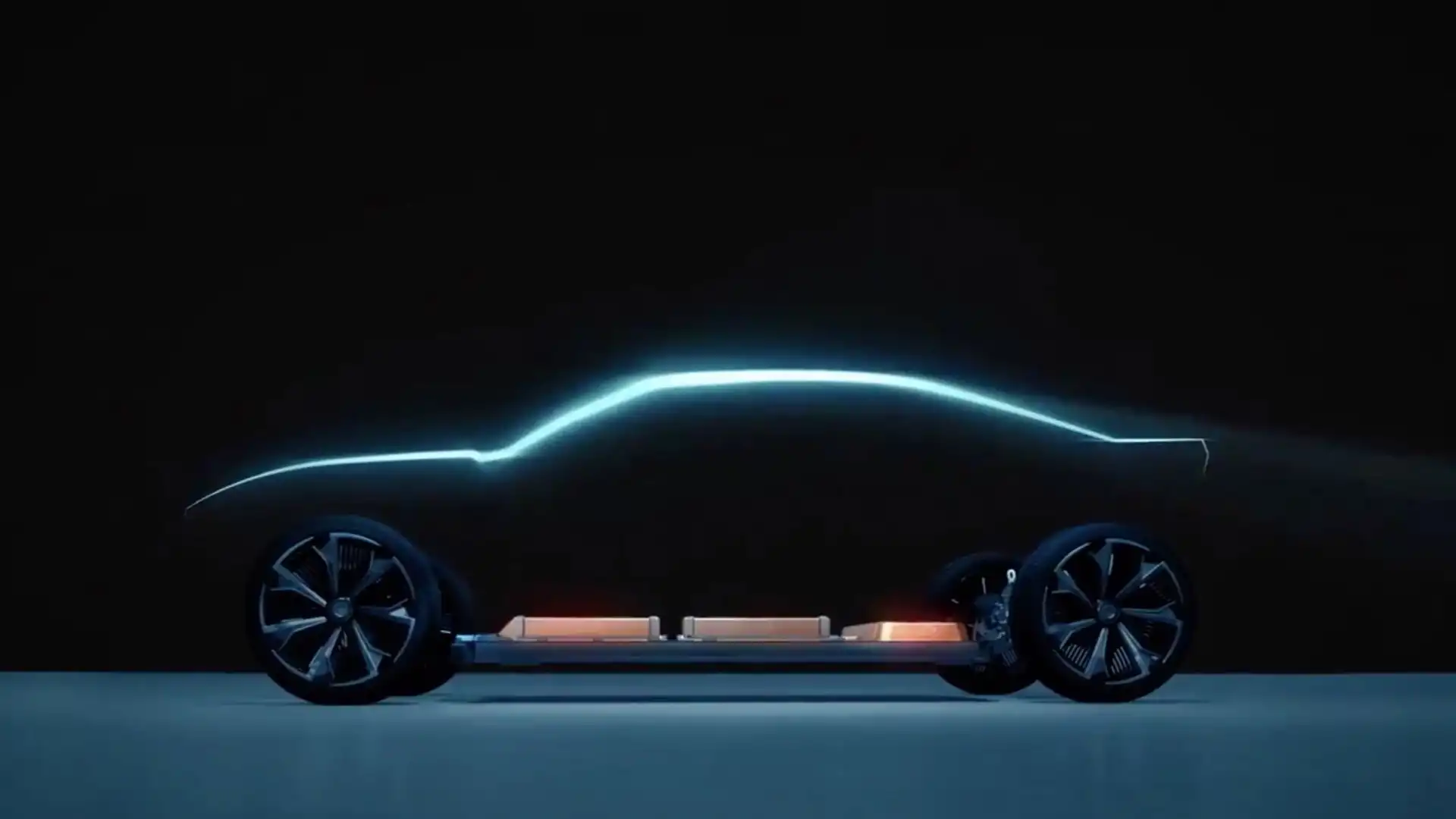

The manufacturing process of lithium-ion batteries involves mixing slurries of cathode and anode material, which are then applied to foil and cut into battery-cell sized pieces. These pieces are then laminated with the separator and stacked in layers, followed by the injection of electrolyte and an aging process. The completed cells are assembled into modules, with multiple modules making up a battery pack.

Overall, the video provides a comprehensive look at the intricate process of manufacturing lithium-ion batteries, shedding light on the essential components that drive the advancement of electric vehicle technology. With the increasing demand for electric vehicles, the role of lithium-ion batteries in powering these vehicles is more crucial than ever, making advancements in battery technology a key focus for the future of sustainable transportation.

Comments on Lithium-ion Battery: How It Works